Home \ Installation Guidelines

Installation Guidelines

Installation Guidelines

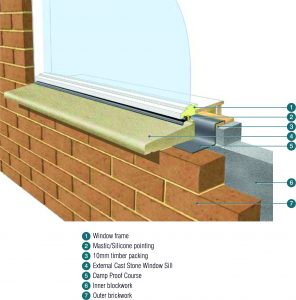

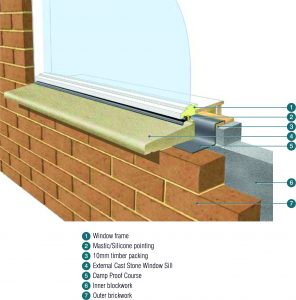

- Suitable provision should be made for a horizontal DPC below the sill

- Typically, cast stone products are designed to be fixed with joint sizes of between 5-10mm between the units

- Sills should be laid on pads of mortar rather than on a continuous bed. Pointing should then be carried out around the sill

- All units should be laid and adjusted to final position while the mortar is still plastic

- Mortar exuding from joints should be cut away without smearing the face of the unit

- Protect all unfinished masonry with polythene

- During hot dry weather, the faces to be jointed should be lightly sprayed with clean water to reduce initial suction and to prevent the cast stone from removing too much moisture from the mortar. If this does occur, there may be insufficient water left in the mortar to fully hydrate the mix and this will result in a dry, powdery joint which may be substantially weaker than anticipated in terms of bond strength. However, it should be noted that the use of water reducing admixtures or other water resistant additives, introduced into the cast stone during manufacture may reduce the effectiveness of spraying the joint with water. Ideally, the correct designation of mortar should be specified in the first instance, to suit the environment.

Cutting

External Cast Stone Window Sills should be cut with a diamond tipped masonry blade which should ideally be water fed. Once cut, all units should be washed down to remove any excess dust. Due regard should be given to protecting the operative in accordance with current Health & Safety considerations for dust suppression and elimination in the workplace.

Alternatively CMS Danskin Acoustics offer a cut to size service from the manufacturing factory in Wishaw, Scotland.